Reynolds Number is a dimensionless

number that describes the fluid flow under given conditions. It is the ratio of

inertial forces to viscous forces and is given by the following equation for

fluid flow through a pipe.

Re = r.Vs.D

/ m

Where, Re = Reynolds Number

r = Density

Vs

= Velocity of flow

D = Diameter of pipe

m = Dynamic

viscosity

The

equation can be rewritten as

Re

= K.Qf. r / D. m

Where, Qf = Flow rate

K = constant value depending on units

Turbine

meters need to be calibrated under field conditions for acceptable accuracy.

The best calibration results are obtained by matching the field Reynolds

Numbers and flow rates.

The

field parameters are collected and entered into the application, along with the

calibration test request data. The program then calculates the field Reynolds

Number and meter calibration facility set up parameters for 2 types of tests:

1. Matching Reynolds Number and flow

rates – calculate calibration pressures

2. Matching flow rates and density –

calculate calibration pressures and Reynolds Numbers

Navigation

The

calculator program comprises four input data screens and one results screen. To

navigate among the input data screens, click on the screen number in the

navigation panel on the left  or click on the

or click on the ![]() buttons in the bottom right hand corner.

buttons in the bottom right hand corner.

Toolbar

![]()

The

buttons on the toolbar in the top right hand corner provide the following

functionality:

New

calculation: ![]() The new page button resets all fields to their

default value to start a new Reynolds Number calculation.

The new page button resets all fields to their

default value to start a new Reynolds Number calculation.

Edit

test criteria: ![]() The pencil button allows you to return to the

first screen, after viewing the results, to change any input data, and

recalculate.

The pencil button allows you to return to the

first screen, after viewing the results, to change any input data, and

recalculate.

Save

results:![]() : This button allows you to save the results of the

calculations in the form of a pdf file.

: This button allows you to save the results of the

calculations in the form of a pdf file.

Help:

![]() View this User Guide.

View this User Guide.

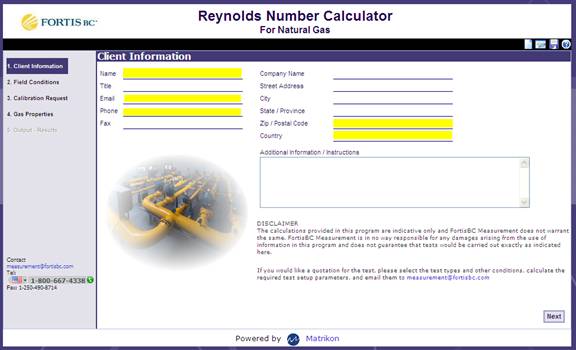

Client

Information

Fill

in your identification and contact information and any additional comments. Click

on ![]() to go to the next screen.

to go to the next screen.

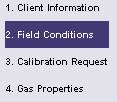

Field

Conditions

Select

either Metric or Imperial as the units you wish to enter

the data. Any values that have already been entered will be converted. All

fields on this page are required and must be within a specific range. Errors

will be highlighted in red with an explanatory message.

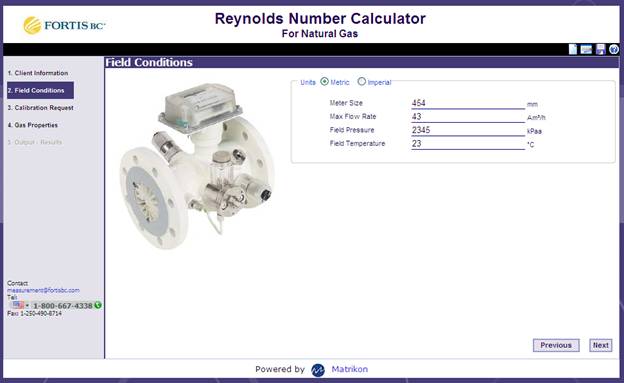

Calibration

Request

On

this screen you select the number of points for meter calibration. Your options

are the standard 5 Point, 2 Point or a custom number from 1 to 10 points. Click

on the required option. If Other is selected, first

enter the number of points![]() , and then

enter the desired flow rates in ascending order.

, and then

enter the desired flow rates in ascending order.

Select

![]() if the meter is to be calibrated additionally

at a pressure other than the field pressure.

if the meter is to be calibrated additionally

at a pressure other than the field pressure.

By

default, the calibration temperature is the same as the field temperature. If

the meter is to be calibrated at some other temperature, then enter the new

temperature here. ![]()

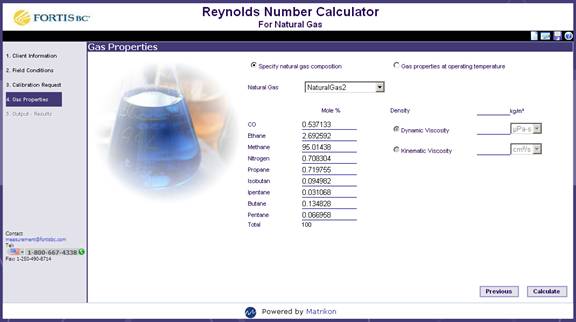

Gas

Properties

On

this screen, the field natural gas properties need to be specified. There are 3

ways of doing this.

1) From the predefined list of gases, select

the gas whose composition most closely matches the composition in the field.

2) If there is no gas whose composition

matches closely, then select the nearest gas and modify the composition,

ensuring that the sum of the fractions adds up to 100%

3) If the density and viscosity are

known at the field pressure and calibration temperature, then select this

option. ![]() Enter the density, and either dynamic

viscosity or kinematic viscosity in the units of your choice. If units are

changed, any entered values are automatically converted. If an additional

calibration pressure was specified in the previous screen, then enter the

second set of density and viscosity values at the additional calibration

pressure and the calibration temperature.

Enter the density, and either dynamic

viscosity or kinematic viscosity in the units of your choice. If units are

changed, any entered values are automatically converted. If an additional

calibration pressure was specified in the previous screen, then enter the

second set of density and viscosity values at the additional calibration

pressure and the calibration temperature.

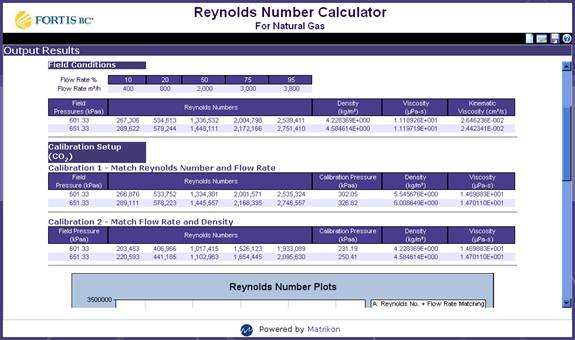

Output

Results

If

the input data or the calibration facility setup parameters are out of range

for the facility, then only the field Reynolds Numbers are

calculated and no output is generated for the calibration setup.

The

calibration test setup parameters are calculated using C02 as the

reference gas. The first chart is a graph of the Reynolds Numbers and Flow Rate.

There is one set of plots for Reynolds Number and Flow Rate matching and for

Flow Rate and Density matching, for each calibration pressure.

Click

on the Save Results button in the toolbar to save the file on your local

computer. To return to the input screens click either the back button on your

browser or the edit icon in the toolbar. To start from fresh form to enter in

all new values, click the blank page icon.